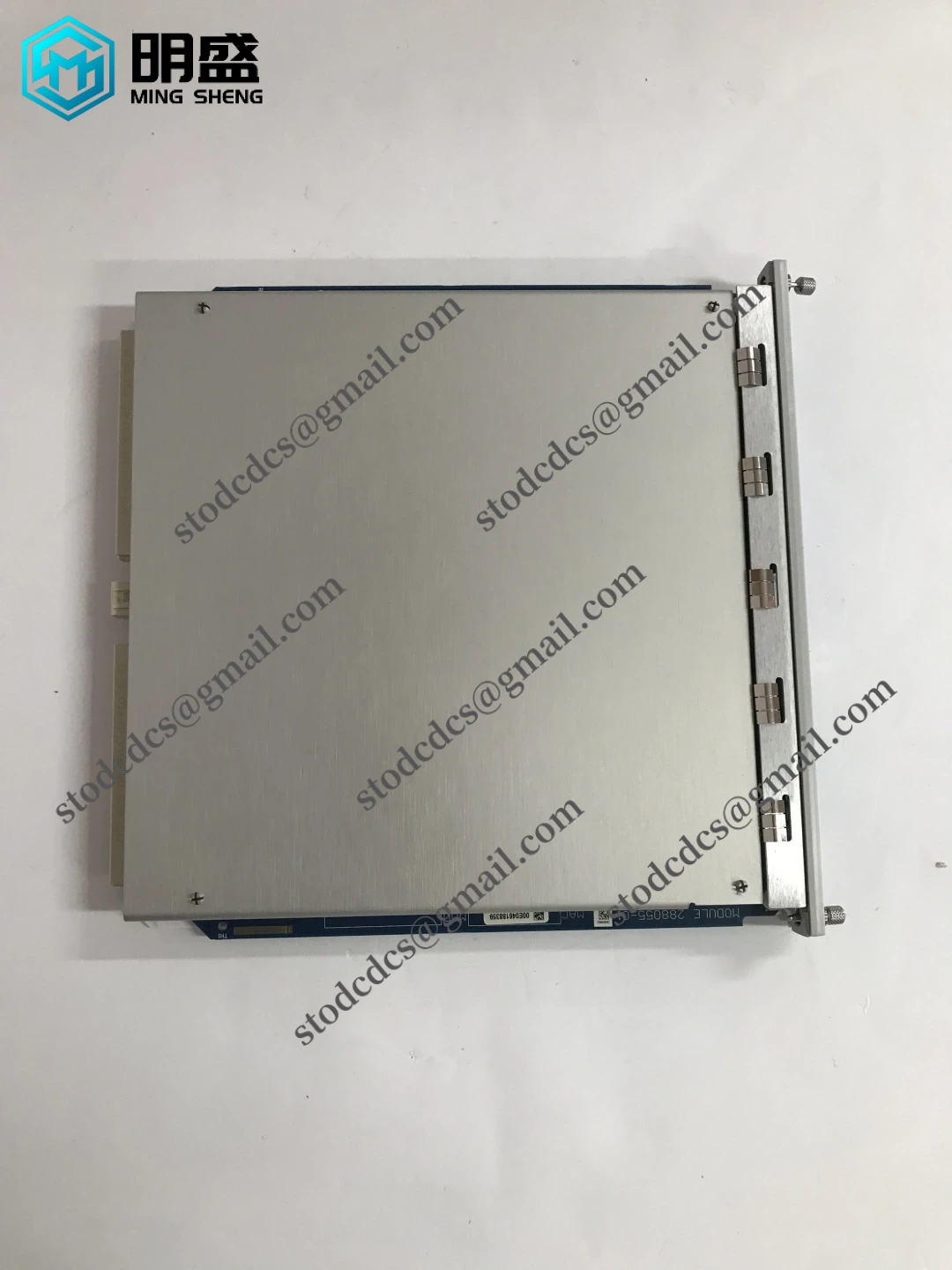

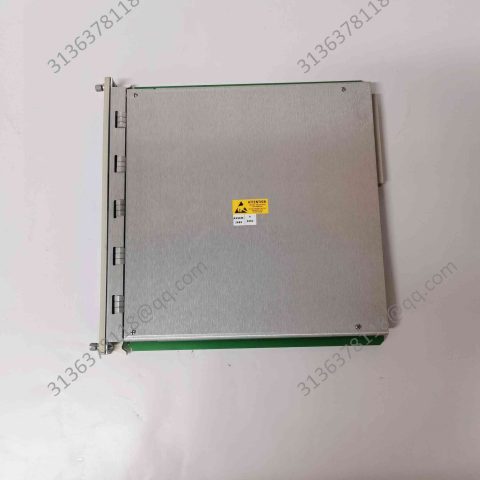

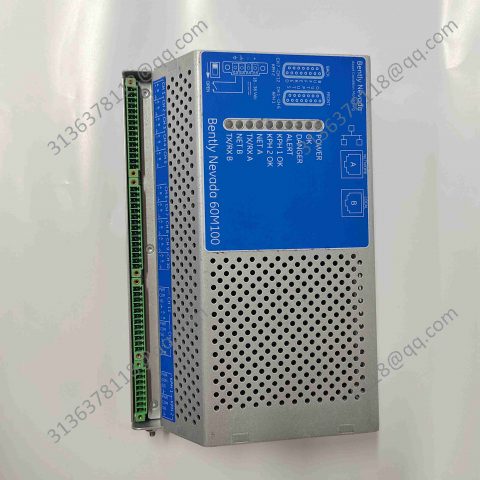

BENTLY 3500-22M 288055-01 高精度振动监测系统模块

这款工业级振动监测模块专为汽轮机、压缩机等大型旋转设备打造,采用军工级传感技术,能实时捕捉设备运行状态下的微米级振动变化。其独特的三维数据采集能力配合智能算法,可提前12-48小时预警潜在机械故障,有效降低非计划停机风险。实际应用中已在发电厂汽轮机组上实现振动监测精度达±0.5μm的行业领先水平。

核心功能与行业定位

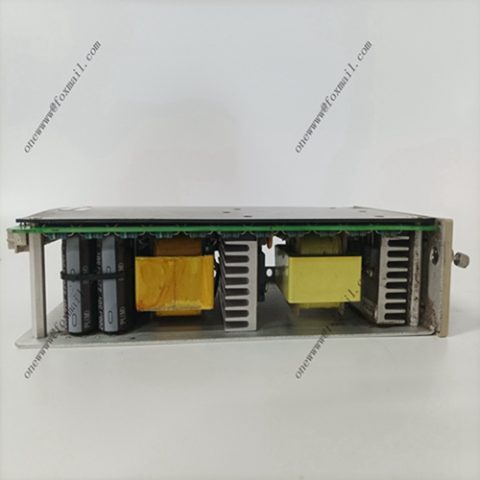

作为BENTLY 3500系统的关键组件,该模块创新性地整合了信号调理、数据处理和通信三大功能。模块支持8通道同步采集,配备专用的相位触发端口,特别适合轴振动与位移的联合分析。在石油炼化企业的离心压缩机监测项目中,其IP67防护等级与-40℃~85℃宽温设计,完美应对高温油气环境下的长期稳定运行挑战。

详细技术参数

| 参数类别 | 详细规格 | 特殊性能 |

|---|---|---|

| 供电要求 | 24V DC(冗余设计) | 支持18-32V宽电压输入 |

| 测量范围 | 0-50mm/s RMS(振动) | 自动量程切换功能 |

| 数据更新率 | 50Hz(常规模式) | 高速模式支持200Hz采样 |

| 通信协议 | Modbus RTU/TCP | 支持OPC UA工业物联网协议 |

| 防护等级 | IP67 | 满足NEMA 4X防腐要求 |

产品优势与品牌矩阵

我们的优势不仅体现在产品的卓越性能,更在于完整的解决方案能力。作为BENTLY NEVADA核心合作伙伴,我们同步提供3500/44、3500/92等配套模块,以及ABB DSQC系列机器人备件、GE Fanuc VMIVME系列控制卡件、Triconex 3008安全模块等全系工控产品。所有产品均通过CE、UL认证,配备专业的现场调试服务,确保从选型到交付的全流程无忧。

Product Overview & Key Features (English)

The BENTLY 3500-22M 288055-01 vibration monitoring module is engineered for precision detection of mechanical vibrations in large rotating equipment. Its advanced sensor technology enables real-time condition monitoring with micro-level accuracy, featuring early warning capabilities through intelligent algorithms. This module integrates signal conditioning, data processing, and communication functions into a compact design that meets the demanding requirements of industrial environments.

As a core component of the BENTLY 3500 system, it supports 8-channel synchronous data acquisition and includes specialized ports for phase-triggered measurements. The IP67 rating and wide operating temperature range (-40℃ to 85℃) ensure reliable performance in challenging conditions, such as high-temperature gas environments commonly found in petrochemical plants. Its modular design allows for seamless integration with existing monitoring systems while maintaining backward compatibility with legacy components.

There are no reviews yet.