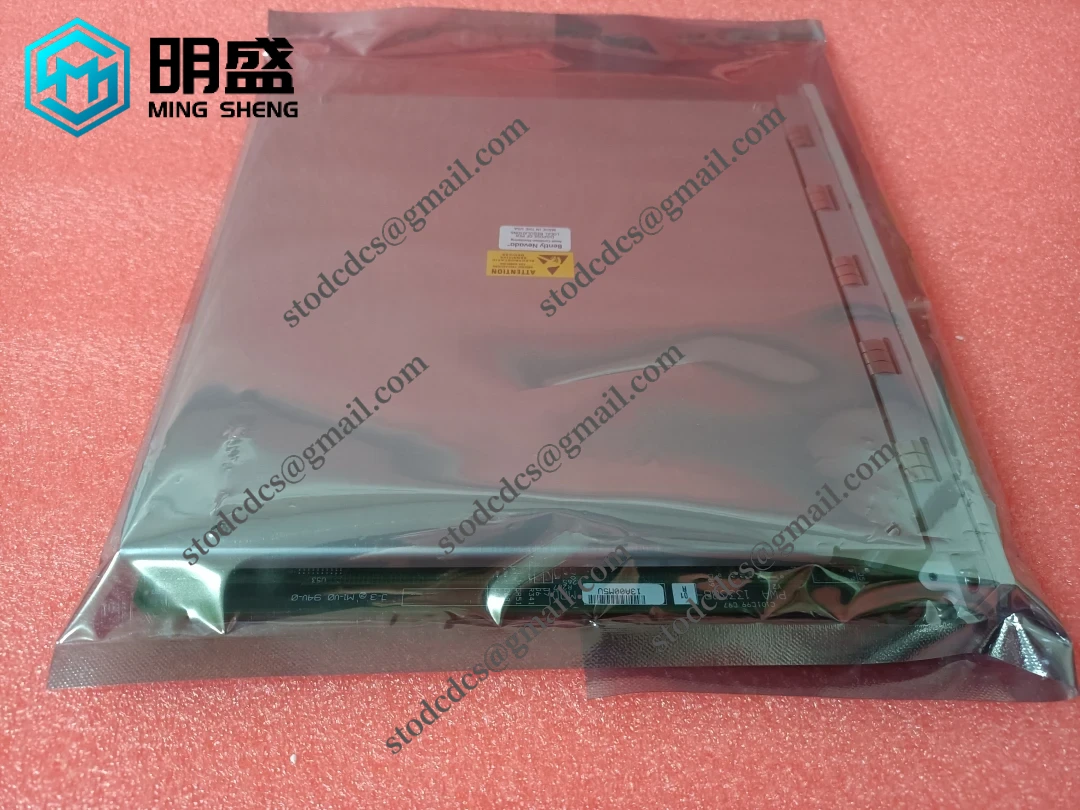

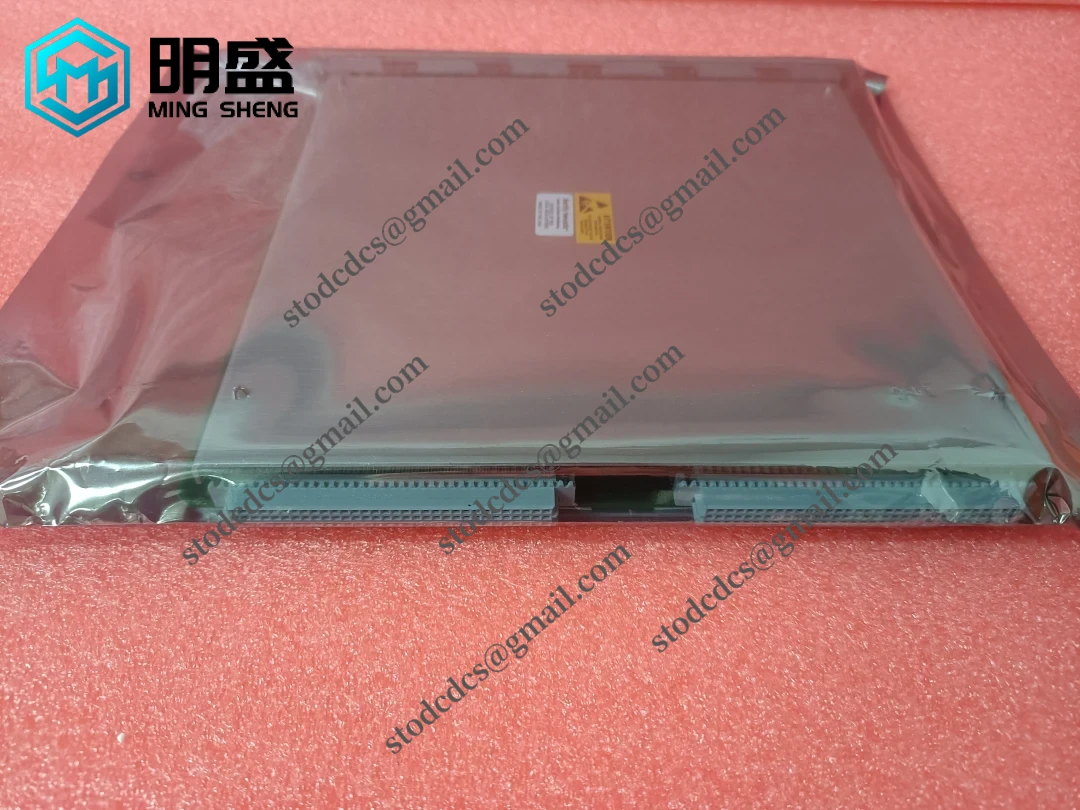

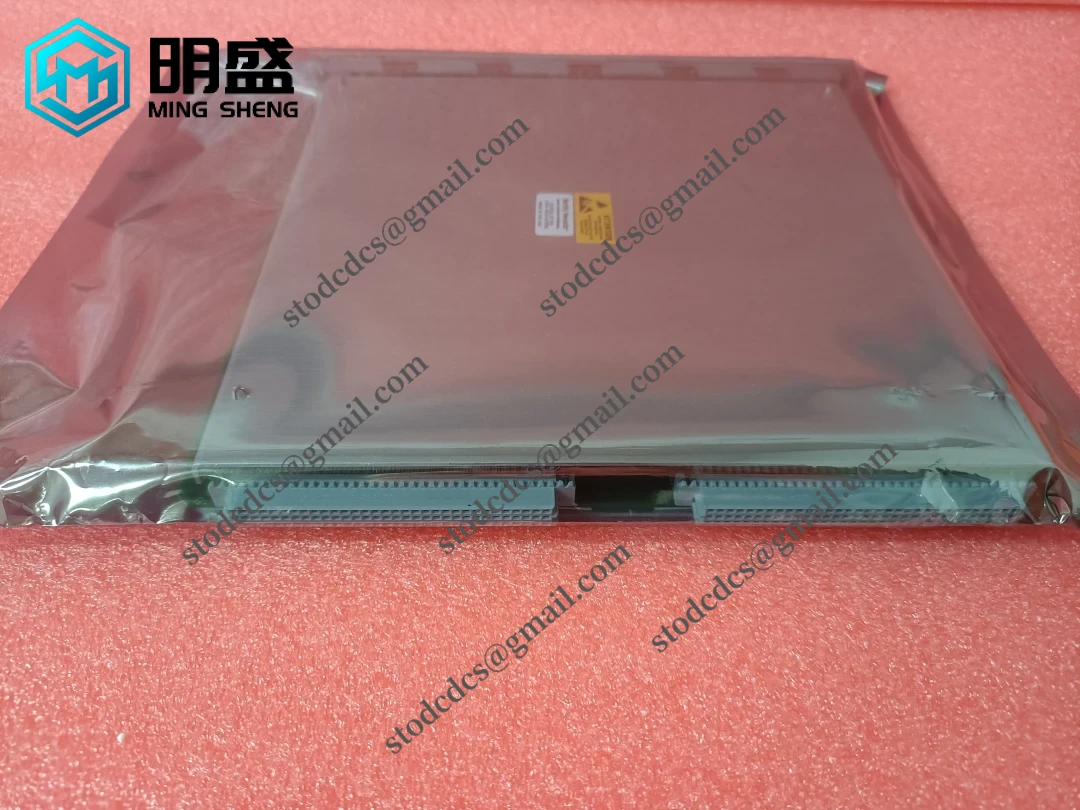

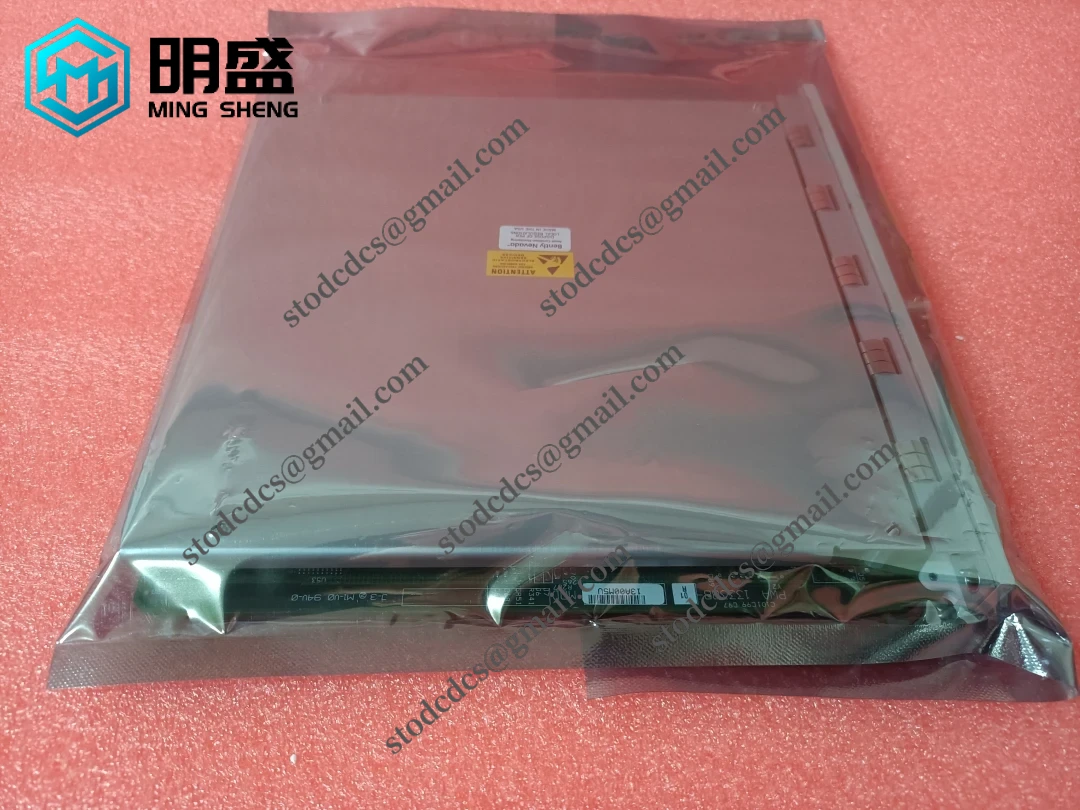

BENTLY 3500/53 133388-01 振动监测模块

这款高精度振动监测模块专为大型旋转机械设计,能实时捕捉设备运行状态数据。通过4-20mA模拟信号与数字通信双通道传输,既可独立运行也可无缝对接DCS系统,帮助用户预防轴承磨损、转子不平衡等常见故障。其实它的核心价值在于把复杂的机械振动信号转化为直观的诊断数据,让设备维护从”事后补救”升级为”事前预防”。

工业设备健康管家

作为3500系统的核心监测单元,这款模块采用磁座吸附+螺纹固定的双安装模式,现场调试时无需停机即可完成部署。内置的智能信号处理芯片能解析振动频谱特征,配合LED状态指示灯实现”看得见”的设备健康状态。特别适合汽轮机、大型电机这类关键设备的7×24小时连续监测。

技术参数详解

| 参数项 | 技术指标 | 特殊优势 |

|---|---|---|

| 测量范围 | 0-50 mm/s RMS | 覆盖常规旋转机械振动阈值 |

| 频率响应 | 5-1000Hz | 精准捕捉轴承故障特征频率 |

| 防护等级 | IP65 | 防尘防水适应恶劣工业环境 |

| 通信协议 | HART/Modbus | 兼容主流工业控制系统 |

| 材质工艺 | 航空级铝合金 | 抗腐蚀性提升30%使用寿命 |

为什么选择这款模块?

作为专注欧美工控产品15年的经销商,我们提供全系列Bently Nevada监测系统备件,包括3500/32、3500/22M、3500/92等核心型号。这款3500/53模块的突出优势在于:

- 双安装模式(磁吸+螺纹)适应复杂现场环境

- 智能自诊断功能降低误报率

- 通过ISO 9001认证的军工级制造工艺

- 支持与GE、ABB、Schneider等主流控制系统集成

同时我们还代理 Bently Nevada、Foxboro、Triconex等品牌的核心备件,如GE的VMIVME系列模块、Foxboro的FBM200系列卡件等,提供全生命周期技术支持服务。

Product Overview (English Version)

The BENTLY 3500/53 133388-01 is a high-precision vibration monitoring module designed for real-time condition monitoring of large rotating machinery. With dual-channel output (4-20mA analog signal and digital communication), it can operate independently or integrate seamlessly with DCS systems to prevent bearing wear, rotor imbalance and other common failures. Its core value lies in transforming complex mechanical vibration signals into intuitive diagnostic data, upgrading equipment maintenance from “post-event remediation” to “preventive maintenance”.

As a core monitoring unit of the 3500 system, this module features dual installation modes (magnetic base + threaded fixation), allowing deployment without shutdown during on-site commissioning. The built-in intelligent signal processing chip can analyze vibration spectrum characteristics, combined with LED status indicators to achieve “visible” equipment health status. Particularly suitable for 7×24-hour continuous monitoring of critical equipment such as steam turbines and large motors.

There are no reviews yet.