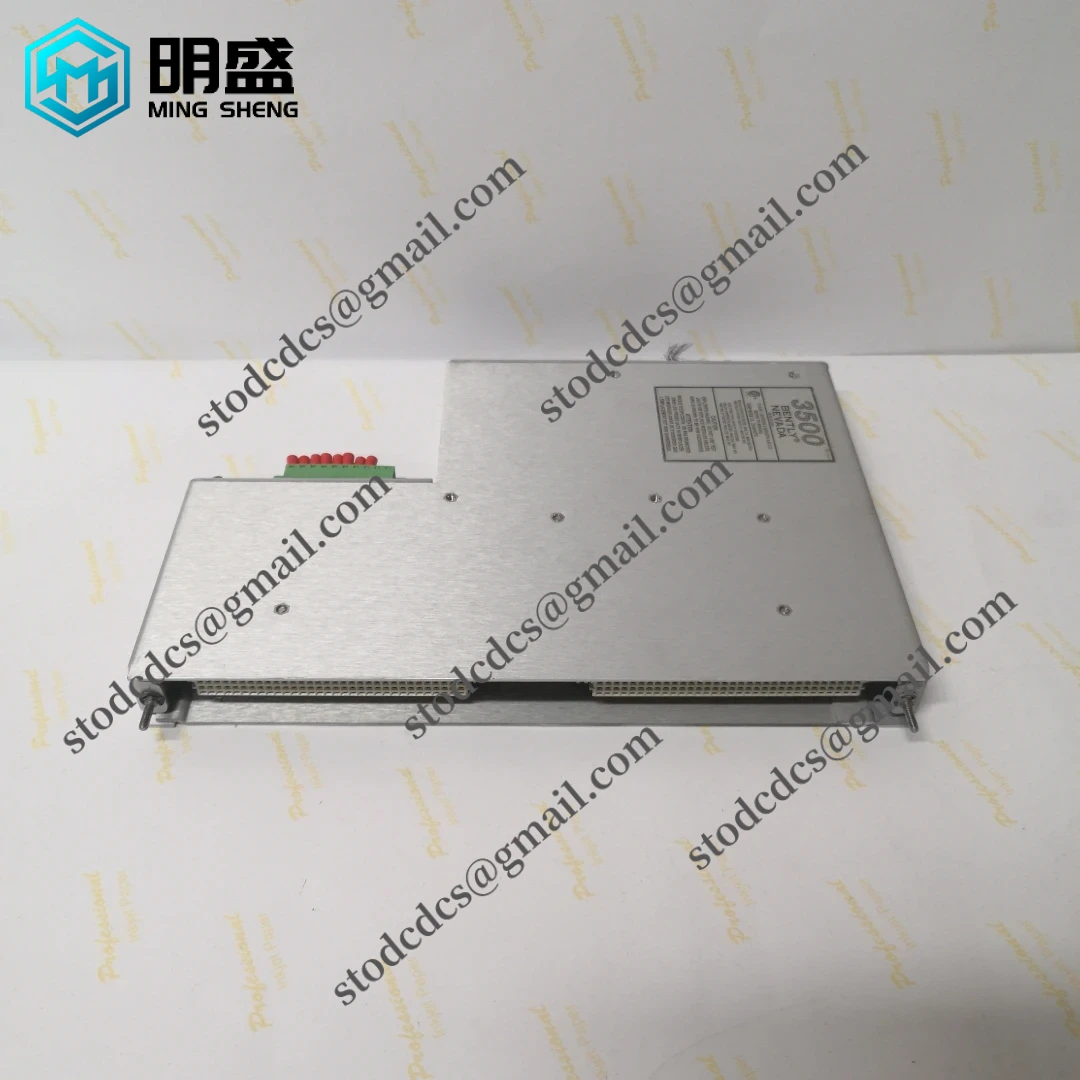

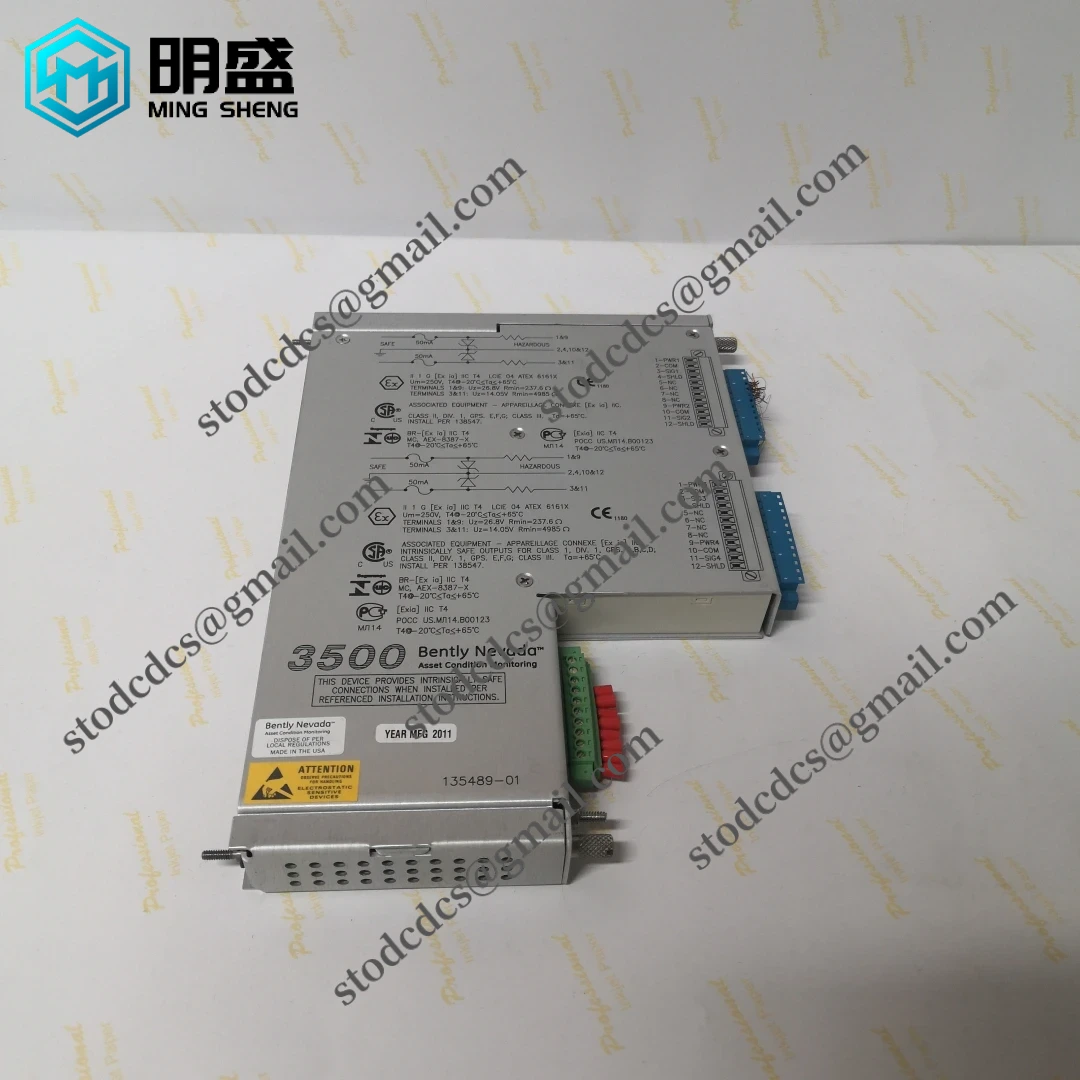

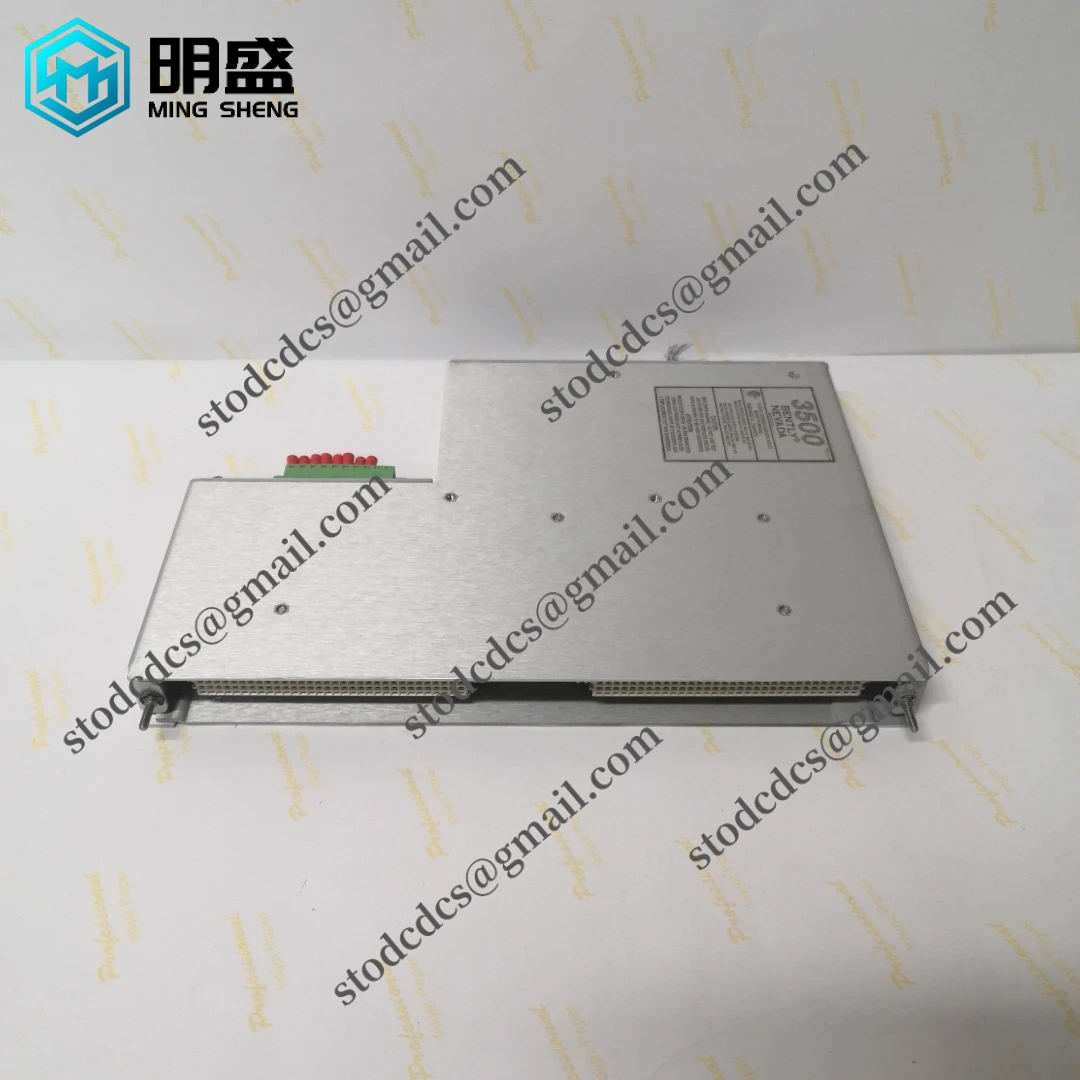

BENTLY 135489-01 高精度振动监测模块

这款专为工业设备打造的振动监测解决方案,其实能精准捕捉旋转机械的细微振动变化。模块采用24V直流供电设计,搭配10kHz高频输出特性,特别适合汽轮机、压缩机等关键设备的实时状态监测。通过持续采集振动数据并建立设备健康档案,帮助工程师预判轴承磨损、转子失衡等常见故障,有效降低非计划停机风险。

工业设备的”听诊器”

作为3500/44监测系统的核心组件,该模块支持与Proximitor探头的无缝对接。其内置的智能诊断算法不仅能实时分析振动频谱,还可通过RS485接口与DCS系统交互数据。美国原厂的精密制造工艺保证了-40℃至85℃极端工况下的稳定运行,特别适用于炼化、电力等连续生产场景。

技术参数深度解析

| 参数类别 | 技术指标 | 特殊优势 |

|---|---|---|

| 信号输入 | 0-200mV/g(可调) | 兼容多种加速度传感器 |

| 采样精度 | ±0.25% FS | 达到军工级测量标准 |

| 通信协议 | Modbus RTU | 支持远程参数配置 |

| 防护等级 | IP65 | 适应恶劣工业环境 |

| 安装方式 | DIN导轨安装 | 节省控制柜空间 |

我们的专业保障

作为BENTLY NEVADA全系产品的授权经销商,我们同时提供3500/32、3500/20等配套模块,以及ABB、FOXBORO等主流品牌的备件服务。所有产品均配备原厂测试报告,支持7×24小时技术响应,确保您获得完整的系统维护解决方案。

BENTLY 135489-01 in English

The BENTLY 135489-01 vibration monitoring module is engineered for precision condition monitoring of rotating equipment in industrial settings. With its 24V DC power supply and 10kHz high-frequency output, this device serves as a critical diagnostic tool for turbines, compressors, and other critical machinery. The module’s advanced signal processing capabilities enable early detection of mechanical issues like bearing wear and rotor imbalance, helping prevent unplanned downtime through predictive maintenance strategies.

As a core component of the 3500/44 monitoring system, it integrates seamlessly with Proximitor probes while offering RS485 communication for DCS system integration. Manufactured to stringent quality standards in the USA, the module ensures reliable operation across extreme temperature ranges (-40℃ to 85℃), making it particularly suitable for continuous production environments in power generation and petrochemical industries.

There are no reviews yet.